Metric Bolt Torque Spec Secrets: Your Ultimate Guide

Ever stared at a bolt, wrench in hand, and wondered, "How tight is too tight?" You're not alone. Knowing the proper torque for your metric bolts is crucial, and frankly, it's kind of a big deal. We're talking stripped threads, snapped bolts, or worse – parts vibrating loose at the worst possible moment. This isn't just about wrenching; it's about precision. So, let's dive into the world of metric bolt torque specifications, measured in good ol' foot-pounds.

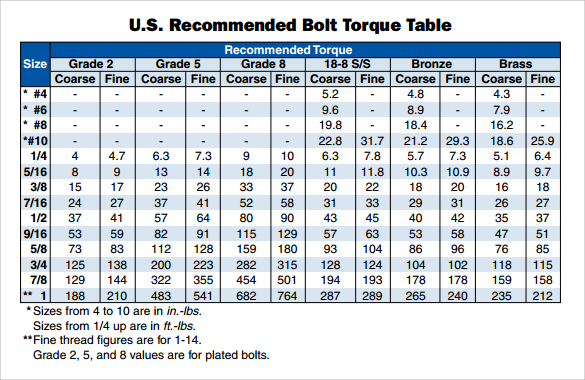

Forget guessing games. Using a metric bolt torque chart expressed in ft-lbs is like having a secret weapon against mechanical mayhem. It's the difference between a solid, reliable assembly and a potential disaster waiting to happen. Whether you're a seasoned mechanic or a weekend warrior tackling a DIY project, understanding these specs is paramount.

So, what exactly is a metric bolt torque specification, and why should you care? It's essentially a prescribed amount of rotational force, measured in foot-pounds (ft-lbs), that you apply to a fastener. This ensures the bolted joint is secure enough to withstand the intended load without damaging the bolt or the materials it’s joining. Think of it as the Goldilocks principle of fastening – not too loose, not too tight, but just right.

The history of torque specifications is intertwined with the rise of standardized engineering. As machines became more complex, the need for precise and repeatable assembly became critical. Over time, engineers developed standardized torque charts and formulas based on factors like bolt size, material, and application. These charts, often expressed in ft-lbs even for metric bolts, became essential tools for ensuring consistent and reliable bolted joints.

Navigating the world of metric bolt torque can be tricky, especially when dealing with ft-lbs conversions. Inconsistencies between different charts and the risk of misinterpreting specifications can lead to problems. One common issue is using the wrong conversion factor, resulting in over- or under-torquing. Another challenge is accounting for lubrication, which significantly affects the required torque. Using a lubricated bolt with a dry torque specification can lead to over-tightening and potential damage.

A key benefit of using a reliable metric bolt torque chart in ft-lbs is preventing damage. Over-torquing can strip threads, shear bolts, or even warp components. Under-torquing, on the other hand, can lead to loose joints, vibrations, and eventual failure. The chart provides the sweet spot, ensuring the joint is secure without risking damage.

Another advantage is improved consistency. Using a chart ensures all fasteners are tightened to the same specification, leading to a more uniform and reliable assembly. This is particularly important in applications where consistent clamping force is critical, such as engine assembly or structural work.

Finally, using a proper torque chart saves time and money. By preventing damage and ensuring consistent assembly, you reduce the risk of rework, repairs, and potential warranty claims.

Always ensure you’re using the correct chart for your specific application. Factors like bolt size, material grade, and thread pitch all influence the required torque. Lubrication also plays a crucial role; be sure to adjust the torque value accordingly.

Advantages and Disadvantages of Using a Torque Chart (ft-lbs)

| Advantages | Disadvantages |

|---|---|

| Prevents damage from over/under-torquing | Potential for using incorrect chart/specifications |

| Ensures consistent bolt tightening | Requires accurate conversion for metric bolts |

| Saves time and money by preventing rework | Lubrication needs careful consideration and adjustment |

Finding a reliable metric bolt torque chart, especially one expressed in ft-lbs, is essential. Consult reputable engineering handbooks, manufacturer specifications, or trusted online resources.

In conclusion, understanding and applying the correct metric bolt torque specifications is fundamental to any mechanical assembly. Using a reliable torque chart, expressed in ft-lbs, is your best defense against stripped threads, broken bolts, and loose connections. By following best practices and paying attention to the details, you can ensure a secure, reliable, and long-lasting assembly. So, grab your wrench, consult your chart, and torque with confidence!

M8 X 125 Bolt Torque Spec | YonathAn-Avis Hai

Stainless Bolt Torque Chart | YonathAn-Avis Hai

Torque Setting For M8 Bolt | YonathAn-Avis Hai

Sae Bolt Torque Chart | YonathAn-Avis Hai

Printable Bolt Torque Chart | YonathAn-Avis Hai

Sae Torque Specification Chart | YonathAn-Avis Hai

metric bolt torque chart ft lbs | YonathAn-Avis Hai

Torque Conversion Table Pdf | YonathAn-Avis Hai

Torque Values By Bolt Size Metric | YonathAn-Avis Hai

Bolt Torque Table Nm | YonathAn-Avis Hai

Torque Conversion Chart English to Metric torque conversion chart of | YonathAn-Avis Hai

metric bolt torque chart ft lbs | YonathAn-Avis Hai

metric bolt torque chart ft lbs | YonathAn-Avis Hai

Metric Bolts Torque Chart | YonathAn-Avis Hai

Printable Bolt Torque Chart | YonathAn-Avis Hai