Understanding Hydraulic Pump Symbols

Imagine a complex network of pipes, valves, and actuators working together to power heavy machinery. How do engineers understand and communicate the intricacies of such a system? Hydraulic pump schematic symbols provide a visual language for representing these components, simplifying complex designs and facilitating clear communication among engineers and technicians.

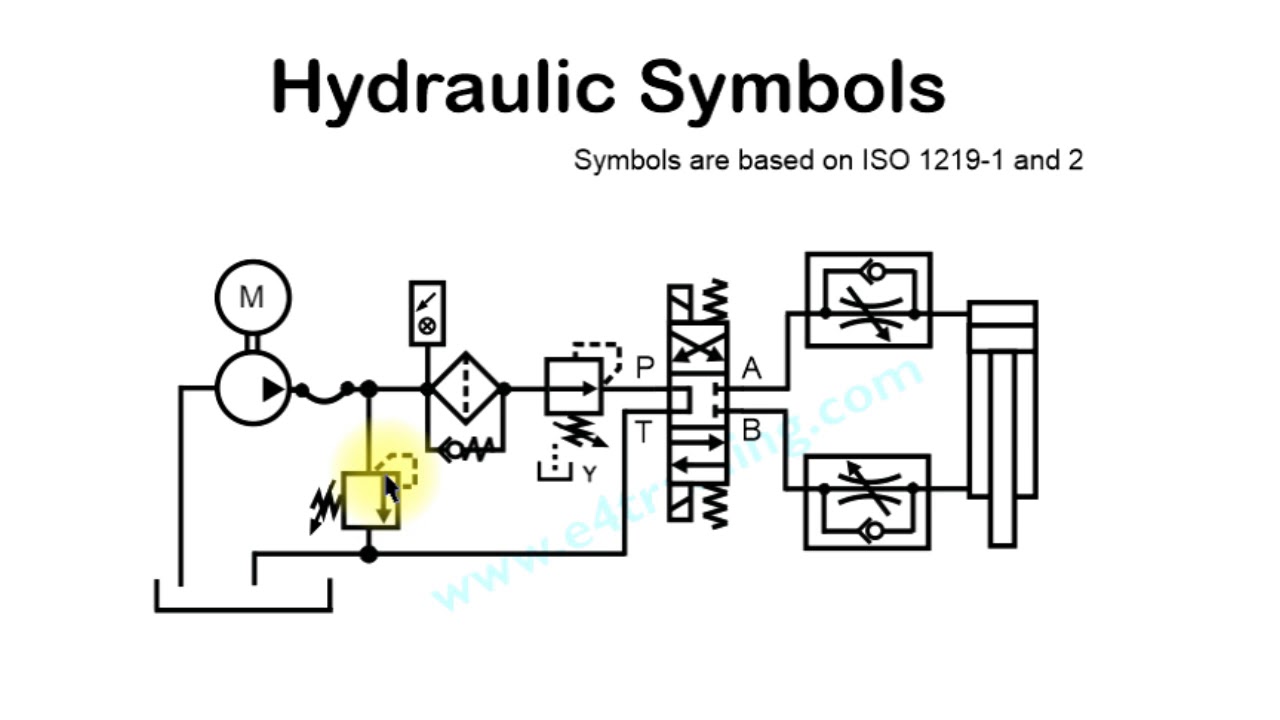

Hydraulic schematics are like blueprints for fluid power systems. They utilize a standardized set of symbols to represent various hydraulic components, including pumps, motors, valves, and actuators. Understanding these symbols is crucial for anyone working with hydraulic systems, from designing and troubleshooting to maintenance and repair.

The need for a universal language in hydraulics arose with the increasing complexity of hydraulic systems. Early systems were relatively simple, but as technology advanced, systems became more intricate, requiring a standardized way to represent components and their interactions. Schematic symbols emerged as a solution, enabling engineers to effectively communicate designs regardless of language barriers or geographical location.

Hydraulic pump symbols in particular hold significant importance. They convey crucial information about the type of pump, its displacement, and its direction of flow. This information is essential for correctly interpreting a hydraulic schematic and understanding the overall function of the system.

Misinterpreting hydraulic pump diagram symbols can lead to several issues, including incorrect system assembly, improper component selection, and ultimately, system malfunction. Accurate interpretation of these symbols is paramount for ensuring proper system operation and preventing costly errors.

A fixed displacement pump symbol typically consists of a circle with an arrow pointing outwards, indicating a constant flow rate. A variable displacement pump symbol, on the other hand, might have an arrow with an adjustable length or a diagonal line across it, signifying its ability to change flow rate.

One key benefit of hydraulic symbols is clarity. They provide a concise and visually intuitive way to understand system layout and component connections. Another benefit is standardization. Using standardized symbols eliminates ambiguity and ensures clear communication across different engineering disciplines and global contexts. Lastly, efficient troubleshooting is facilitated by schematic symbols. Technicians can quickly identify faulty components by tracing the flow path and pinpointing problem areas within the schematic.

Creating an effective hydraulic schematic involves several steps. Begin by identifying all components in the system. Next, select the appropriate symbols for each component based on industry standards. Arrange the symbols logically on the drawing, showing the flow path and component interconnections. Finally, label all components and lines clearly for easy identification.

Advantages and Disadvantages of Standardized Hydraulic Symbols

| Advantages | Disadvantages |

|---|---|

| Clear communication | Requires initial learning |

| Simplified design representation | Can become complex for very large systems |

| Efficient troubleshooting | Potential for misinterpretation if not used correctly |

Best practices for implementing hydraulic pump symbols include adhering to ISO standards, using clear and consistent labeling, organizing the schematic logically, and ensuring proper scaling for readability.

Real-world examples of hydraulic pump symbol usage can be found in various industries, such as automotive, aerospace, and manufacturing. For instance, the hydraulic system of a construction excavator relies on these symbols to represent the pump that drives the boom, arm, and bucket.

A common challenge is the complexity of some symbols. The solution lies in proper training and access to comprehensive symbol libraries. Another challenge is maintaining consistency in large schematics. Using CAD software and adhering to standardized drawing practices can address this.

Frequently asked questions include: What is the symbol for a fixed displacement pump? What does the arrow in a pump symbol represent? How do you differentiate between pump and motor symbols? What are the key components of a hydraulic schematic?

Tips for working with hydraulic symbols include utilizing online symbol libraries, practicing drawing simple schematics, and referring to industry standards.

In conclusion, hydraulic pump schematic symbols play a vital role in the design, analysis, and maintenance of fluid power systems. Understanding these symbols is essential for engineers, technicians, and anyone working with hydraulics. By using standardized symbols, we can ensure clear communication, streamline design processes, and enhance troubleshooting efficiency. The benefits of using these symbols far outweigh any initial learning curve. Embrace these visual tools to improve your understanding and proficiency in the world of hydraulics. Further exploration can be done by referencing ISO standards and specialized hydraulics handbooks. This will not only solidify your understanding but also broaden your knowledge about other elements within hydraulic schematic diagrams.

Hydraulic Pump Schematic Symbols | YonathAn-Avis Hai

Hydraulic Pump Schematic Symbols | YonathAn-Avis Hai

Hydraulic Pump Schematic Symbols | YonathAn-Avis Hai

Schematic Symbols For Hydraulic Systems | YonathAn-Avis Hai

Hydraulic Circuit Diagram Symbols | YonathAn-Avis Hai

Hydraulic System Schematic Symbols | YonathAn-Avis Hai

Hydraulic System Drawing Symbols | YonathAn-Avis Hai

Basic Hydraulic Pump Schematic Diagram | YonathAn-Avis Hai

Hydraulic Pump Schematic Symbols | YonathAn-Avis Hai

Hydraulic Motor Schematic Symbol | YonathAn-Avis Hai

Hydraulic Pump Schematic Symbols | YonathAn-Avis Hai

Hydraulic Schematic Symbols Explained | YonathAn-Avis Hai